4 Post Lift Features

Most automotive shops use hydraulic car lifts for raising vehicles to a comfortable working height for better productivity when they are serviced. The focus for this document will be on 4 post car lifts.

Within the above ground 4 Post Lift category there exist a wide range of capacities and several different styles. These different styles are classified in only one type. That type is the “wheel engaging multi-post lift”. Most commonly configured as a four post surface-mounted lift, this is the primary type of lift used by many muffler, oil change, and transmission shops as well as those shops that perform wheel alignment services. It allows the vehicle to be driven onto two runways and lifted by its tires, exposing the underside of the vehicle. These lifts are also referred to as wheel contact or “drive-on” lifts.

Who Buys 4 Post Lifts?

The drive-on four post car lift comes in several styles that are design specific to improve the user’s certain needs. One style that has gained in recent popularity is built for the car enthusiasts and collector car market. It has its own style that allows for servicing and storing cars on top and below the runways. This allows the enthusiast to use his shop space more efficiently without the expense of adding on to his shop. Not only do they provide more storage space, but just like the professional service centers, jacks can be added to these lifts to provide for wheels free service. The enthusiasts drive-on lifts also come in a variety of sizes that can allow enough height under the runways for a full size truck or SUV if needed.

Other features found on the four post enthusiasts lift are:

- No need to be bolted to the concrete on models that are certified to be “free standing”.

- Caster kits make the lift portable to move to another bay.

- Drip trays that collect leaks and prevent the car on bottom from being dripped on.

- Jack trays that allow a scissor jack or bottle jack to be placed for lifting the wheels free.

- Hydraulic jacks designed to slide between the runways for lifting the front or rear end wheels free.

- Operates on standard 110 volt power.

- Best application and drive-on clearance for extremely low vehicles.

Direct-Lift Pro-Park 8 Standard

Enthusiasts Lift

Another popular style of drive-on lift is the commercial grade 14,000 lb. capacity lift. The dimensional range of this style is popular with independent repair shops as well as car dealerships because it can handle a wide range of vehicles without changing any setup. Runways are typically bolted into place at a width that accommodates narrow vehicles and are also wide enough to handle wider tread widths. This makes setup time minimal which leads to a more productive work bay.

What Kinds of Jobs Can You Perform Using a 4 Post Lift?

Popular services for this lift are:

- Quick Lube

- Quick Inspection of Issues

- Transmission Service and Muffler Repair

Quick lube service lifts usually have ramps on both ends for a faster and more convenient drive through capability.

Advantages of Drive-on Lifts

1) A vehicle can be raised safely even when its engine has been removed. Trying to lift such a vehicle on a frame contact lift can be dangerous because the center of gravity has been changed and the load could become unbalanced.

2) The center of the underside of the vehicle is accessible. This is important for exhaust system and transmission work.

3) For quick, easy service, the vehicle requires no set up of lift adapters.

4) Wheels are in contact with the wheel ramps. This is necessary for wheel alignment and exhaust work.

Forward CR-14 Commercial Grade Lift shown with optional RRJ-70G Hydraulic Jack.

Lifts for Wheel Alignments

Another popular application for the commercial grade 4-post lift is wheel alignment service. The cable style lift has independent locking ladders in each column that allow for precise leveling at each corner which is critical for accurately measuring wheel alignment angles. Once levelled, these lifts can simply be raised to the preferred height and set into the nearest locked position for a precise level condition. The alignment versions of these lifts can be equipped with front turntables and rear slip plates to allow complete four wheel alignment service. Add two roller jacks and both the front and rear can be raised to access all four wheels. Some models have an “open-front”, meaning the front crossrail has been removed to allow easy access under the front end without having the beam in your way.

Wheel-Free Roller Jacks

On a wheel contact lift, the wheels are supported unless a wheel-free roller jack is used. These jacks, which are air powered and/or hydraulic, are used to raise either the front or rear of the car for wheels free work. After the vehicle is raised, the jack is lowered onto a mechanical safety latch. When using one of these jacks, keep hands clear and be sure to extend each of the lift arms an equal amount to avoid uneven loading. Be sure that a wheels free jack is lowered all of the way before driving into or out of the lift.

OR-14 Four Wheel Alignment Lift with Open-Front Design, Front Turntables, Rear Slip Plates and 2 RJ-70 Roller Jacks.

Surface Mount 4 Post Lifts

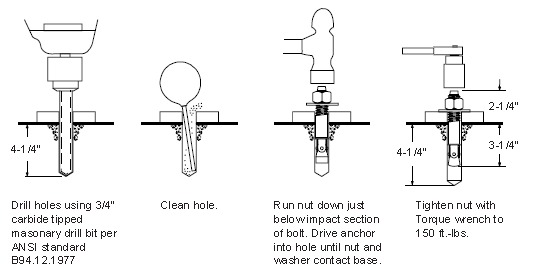

Above ground surface mount lifts became popular in the 1970’s. They are mounted completely above the concrete floor. Different lifts have different concrete requirements. Most surface mount lifts require a minimum of 4” depth concrete with a minimum compressive strength of 3000 PSI to support the lift columns and/or anchor bolts (Enthusiast style lifts do not require anchoring, but can still be anchored if desired). Lifts with higher rated capacities can require a minimum of 6” depth of concrete. Anchor bolts must be torqued to the manufacturer’s specification and checked periodically according to the maintenance guide in the lift’s manual. There are also specifications for the minimum amount of depth the anchor bolt needs to be embedded in the concrete. For example, most 4-post lifts up to 14,000 lb. capacities will require an anchor bolt that is 5.5” length by either ⅝” or ¾” width with a minimum embedment depth of 3.25”. This means once the bolt is torqued to spec, the minimum amount above the floor must be no more than 2.25” to achieve the minimum of 3.25” embedment. Follow the particular lift models manual for exact dimensions.

Ease of installation is one advantage of surface mount lifts. They are also relatively portable (enthusiast models are portable without anchors) and can be relocated in another location in case a business or shop owner decides to move to another location. They also do not have the problem of pollution of the ground water like an in-ground lift, if a hydraulic fluid leak occurs.

A surface mount lift is also easier to maintain or repair because it requires no excavation. Surface mount lifts are also less likely to leak oil into the ground (an environmental concern).

One of the most popular types of surface mounted lifts is the four-post wheel engaging type. It has four posts, two lifting crossrails, each one supporting two drive-on runways. The crossrails are synchronized so that they travel as level and together as possible. To keep the two crossrails moving together, steel cables, chain, synchronized motors or hydraulic circuits are used. The most common synchronization type in the USA is the steel cable.

The hydraulic cylinder, steel lifting cables and pulleys are shown under the powerside runway.

The lifting cables are attached to each post by routing from the hydraulic cylinder block through the powerside runway then distributed by a series of pulleys to each post. The cables carry the lift load and distribute it evenly to each column. The load is borne by the cylinder, cables, crossrails, columns and runways. Adjusting the cables and lock ladders at each column allows the safety locks and runways to be level and the safety locks to engage at the same time. A secondary safety lock system is used on the most current styles that are certified. This secondary lock system will lock into place in the event of a slack cable condition. Each of the 4 cables has its own safety lock system. The hydraulic system consist of an electric power unit, hydraulic hose and cylinder. The power unit includes the electric motor, pump and reservoir tank all in one unit.

Electric / Hydraulic Power Unit

The electric motor requires either 110 or 220 volt power on a 30 amp circuit. Most shops will prefer to drop the power down from the ceiling for hookup to the motor switch box as per local code. The 110 volt power units are supplied with the standard male plug with a short cord. The hydraulic pump is mounted between the motor and the reservoir tank. The pump is equipped with valves that have preset pressure limits to prevent lifting over the rated capacity. DO NOT ATTEMPT TO ADJUST THE FACTORY SETTINGS OF THE PRESSURE VALVE. When the up button is pressed the fluid is pressurized and sent along the hose to the cylinder to provide lift to the cables, crossrails and runways. The pump also has a lowering valve that is activated by the down lever. The down valve allows the fluid to return to the reservoir tank while lowering the lift.

How to Mount a 4 Post Lift

To install a 4 post lift, it’ll be best to follow specific product instructions found in the manual. Your manual will guide you through the entire process of installation. Otherwise, consider reaching out to have your lift professionally installed. Having a team of professionals take on the feat of putting together your lift can save you time and effort, and if you don’t have a team of volunteers to help you raise your lift to a vertical position, you’ll need the manpower.

Does a 4 Post Lift Need to be Anchored?

When you search for this question, you’ll receive different answers depending on the product people are referring to. The best answer is to check the lift’s manual since not all 4 post lifts need to be anchored. Some 4 post lifts are free standing while commercial grade 4 post lifts come with anchors and bolts to mount the lift on a concrete floor.

4 Post Lift Operation Safety Tips

Training in the proper use of the lift is mandatory before attempting to lift a car. Although lifts have an excellent safety record, vehicles can be loaded improperly. When a vehicle comes down by accident, this is usually due to carelessness, misuse, or neglected maintenance. The American National Standards Institute (ANSI) and the Automotive Lift Institute (ALI) have set the American National Standard (ANSI/ALI ALOIM - Sept 2008) for automotive lifts. This standard list safety requirements for operation, inspection, and maintenance of lifts. It requires annual lift inspection by a qualified lift inspector. ALI is also working on a new certification for lift inspectors. This annual inspection is designed to keep automotive lifts in good operating condition. For more information visit the ALI website www.autolift.org.

Safety Note - Remember that you are lifting a vehicle that weighs several thousand pounds. The car must be correctly spotted on the lift. When driving a vehicle onto a wheel contact lift, be sure that the front tires are centered, at equal distances from the edges of the ramps. These lifts have secondary stops for roll-off protection at the front and rear. After spotting the vehicle, always use manual wheel chocks to prevent the car from rolling.

Lift Operation Safety

- If there are any problems with the lift, do not use it. See your supervisor immediately. Do not take chances.

- Be certain that the wheel chocks are in place before lifting.

- Read operations and safety manuals before using lift.

- Proper maintenance and inspection is necessary for safe operation.

Safety Note - The weight of the vehicle must be distributed evenly. If using a 9,000-lb. capacity 4-post lift, each end of the lift is rated for 4,500-lbs. Do not overload one end of the lift.

- All lifts have a safety latch system to be used once the desired lift height is reached. Always lower the lift into the locked position before going under the vehicle. Never use a lift that not able to engage the safety latch system. Tall jack stands are often used to assist load changes while working on a lift.

- The lift area should be clean with no grease or oil on the floor. Hoses, extension cords, and tools should be stored in the places where they belong.

- Do not allow customers to drive their own vehicle onto the lift. Insurance companies usually prohibit customers from being in the lift area.

- Be sure that the lift has adequate capacity to lift the weight of the vehicle. If the vehicle contains any loads inside, in the trunk, or in the bed of a truck, the center of gravity will be affected and the vehicle may be unsafe to lift.

- Be sure that the lift is all of the way down before attempting to drive a car on or off it.

- Before lowering a vehicle, be sure to alert anyone nearby. Be certain that no tools or equipment are below the car. All of the car’s doors should be closed.

Safety Tips Guide can be purchased from ALI website store at www.autolift.org.

Related: